Composites, redefined.

A small agile company integrating advanced systems. Applying cutting edge composites technologies to create solutions for part, tooling, and process development.

Prototyping

If you can dream it, we can build it. Across industries, we offer our global customers a level of thinking and passion they cannot find anywhere else. We quickly and efficiently bring designs to reality with production representative parts.

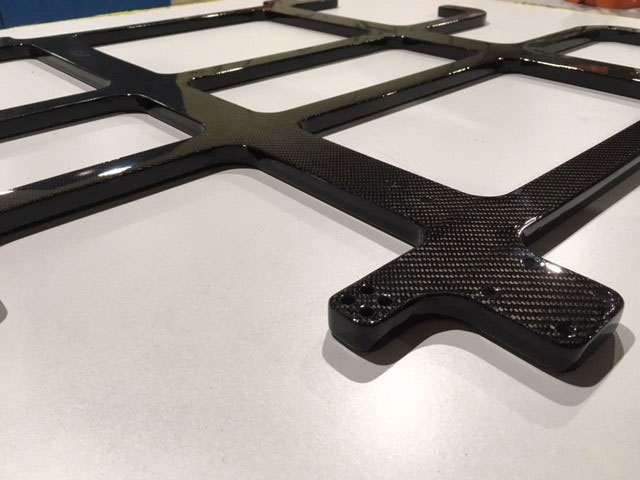

Tooling

Cynergy Composites excels in advanced tooling solutions, offering expertise in Vacuum Infusion and Vacuum Assisted Resin Transfer Molding (VARTM). Our services span the design, development, and manufacturing of molds for producing Class A surfaces and complex, multi-section removable insert tooling. Specializing in large-scale, challenging parts, we deliver high-quality, innovative solutions tailored to the needs of diverse industries, enhancing both production quality and efficiency.

Fireproof Phenolics

Cynergy Composites has developed cutting-edge tooling and composite processing solutions tailored to maximize the performance of advanced Phenolic Resin Systems. These systems are renowned for their superior performance in critical applications, offering unmatched protection against extreme conditions such as high heat, prolonged open flame exposure, and thermal runaway events. Our innovative approach ensures repeatable precision in manufacturing processes, setting new industry standards for safety and efficiency in fireproof materials.

Manufacturing & Production

Our expansive 20,000 sq ft composites manufacturing facility is optimized for superior performance, integrating advanced technology and stringent security measures to serve a wide range of industries. By utilizing composite materials for updating and improving the machinery used in manufacturing, companies can realize savings in costs and time. Composite materials such as carbon fiber are lighter and stronger than traditional metal materials used in manufacturing, and saving weight reduces the manufacturing cycle time, and decreases maintenance costs due to moving less mass. Invest in your business by working with Cynergy to find efficiencies and savings you didn’t even realize were possible before! Here's a detailed overview of our key offerings:

SPE Innovation Award Winner

Cynergy Composites proudly received the "Innovation Award" at the 2018 Society of Plastic Engineers Automotive Composites Conference Exhibition in Novi, Michigan. This recognition was for our pioneering development of heated Carbon Fiber/Epoxy closed cavity tooling designed for high-pressure resin transfer molding (HP-RTM) with 'Snap-Cure' high-rate production toughened epoxy resin systems. This innovative tooling solution has significantly advanced the production processes for prototypes and validation parts, reinforcing our role as industry leaders in composite manufacturing technologies.

World-Renowned Composites Research

Cynergy Composites Inc. is at the forefront of composites research, collaborating internationally on R&D with Hexion to enhance tooling and process innovation. This partnership focuses on developing prototypes and validation parts for OEM Automotive, along with 'PPAP' Pre-Production Approval Parts, which are crucial for automotive manufacturing processes.

Stephen Greydanus, NA Automotive Development Manager at Hexion, praises our approach: “Every component part has its own unique and inherent design challenges. Cynergy Composites’ biggest asset is its ability to creatively 'think outside the box'. Creating tooling that is clever and efficient.” This endorsement underscores our commitment to innovation and excellence in the composites industry.

2022 American Festival of Speed Champion

Triumphing at the M1 Concourse, our GT-1 CF car clinched the title for Best Supercar, showcasing the exceptional capabilities of tooling owned by CCI.

2021 © Cynergy Composites